Flushometer Piston Or Flushometer Diaphragm? How to Choose the Right Flushometer for Your Project

Mar 27th 2024

Despite the fact that flushometer piston and diaphragm flushing technologies have been around for decades, builders and engineers still have trouble deciding which one to use.

It's not clear why but the hesitation to use piston over diaphragm or vice versa, does not stem from any notion that one is better than the other.

Although diaphragm flush valves are ideal for most commercial restrooms, certain environmental conditions may necessitate the use of piston valves.

Before we talk about how you can choose which one to use for your project, let’s first talk about how the flushometer technology works.

The Flushometer Piston and Diaphragm

There are two kinds of flushometers: the piston and the diaphragm. How each operates is basically the same.

The valve is separated into two chambers in both types: a larger high-pressure chamber and a smaller low-pressure chamber. The piston or diaphragm resting between the chambers is displaced when the water is flushed and the water pressure within the chambers changes.

The main difference is that diaphragms use rubber valves, whereas pistons use molded cup (piston) valves. These valves are located in between the two water chambers.

What gives flushometers an advantage over other flushing mechanisms is the use of a pressurized water supply.

In a gravity-assisted tank toilet, the water for the flush is collected in the tank first. When the tank toilet is flushed, water pours into the fixture by gravity. The weight of the water in the tank provides the energy for the flush.

In contrast, pressure-assisted flushometers, rely on supply pipe pressure and flow. This results in more energy behind the flush, which is important in a commercial setting. Flushometers also reset faster than gravity toilets (there is no refilling period), which makes them perfect in high-traffic restrooms.

Which Technology Is Better for Your Project?

When choosing and installing a flushometer, the pressure and water volume requirements for the valve model must be considered. Understanding the installation requirements is essential for successful valve operation.

There are three factors that you should consider when deciding which one to use for your project: restroom traffic, water quality, and operating conditions.

Restroom Traffic

Identifying what kind of traffic your restroom will have is perhaps the biggest factor you should consider when deciding what kind of flushometer you should use. The performance of your flushometer is dependent on the kind of traffic you'll have.

There are two types of traffic patterns: heavy traffic and low traffic. The diaphragm technology is used in high-traffic situations, such as those you'll find in airports and sports stadiums.

The diaphragm technology can handle the quick recovery needed to flush almost immediately after the last flush (which is typical of restrooms with high usage).

On the other hand, when there is low traffic, both flush valve piston and diaphragm can perform well.

Water Quality

Water quality is another important factor to consider. Water quality affects the performance and reliability of the flushometer.

The water characteristics that affect the performance of flushometers include the following:

●Water pH

Any high corrosive or caustic pH levels will affect the strength of rubber materials in flushometer assemblies.

●Solid particulate in the water

Suspended solids or solid particles like sediment, sand, algae, and others, that are present in water can have an impact on the flushometers' sealing surfaces.

●Chlorine concentration

Chlorine in high amounts can cause a variety of problems. For instance,

some elastomer compounds (like rubber parts) will degrade, necessitating service sooner than intended.

●Conductivity

Dissolved salts and other inorganic compounds can conduct electrical current, so when water salinity increases so does water conductivity (or the ability of water to pass an electrical current).

Conductivity can cause metal sealing surfaces to deteriorate, which means that poor sealing may result later on.

●Biomass

By slowly piling up in high flow channels, soluble "biomass" in water can choke narrow openings.

The flushometers physical components when subjected to wear and tear of these kinds will lead to early deterioration.

The deterioration of the piston type, particularly, is influenced by the quality of the water supply. Bowl flushing performance gradually deteriorates from constant abrasion in the primary lip seal.

This will also result in the main high-pressure seal being compromised, resulting in tiny leaks and reduced performance of your flushometers.

Diaphragm valves can also deteriorate over time since the rubber material flexes constantly.

As diaphragms get older, they may become more flexible, allowing more water to pass through and making your flushometers less efficient with each flush.

Operating Conditions

Harsh operating environments can cause a flushometer that isn't designed to work in these settings to fail, operate inefficiently, and waste instead of save water.

Operating conditions, like water quality, should be considered when choosing what flushometer technology to use.

In low-pressure and weak-system settings, piston technology is the better choice. However, if there is high water pressure, the diaphragm may be a preferable option.

Your Takeaway

Understanding the environment and recognizing the strengths of each technology are critical to making the best decision on what flushometer technology you should use in each of your projects.

It's not a one-size-fits-all answer, nor is it a case of one flushing mechanism being superior to another. It's always a case of matching the right technology with the environment it will be installed in. When it's correctly matched, both technologies offer great performance.

In other words, the number of people using the restroom, the quality of the water, and the operational conditions all should play a role when you're choosing flush valves.

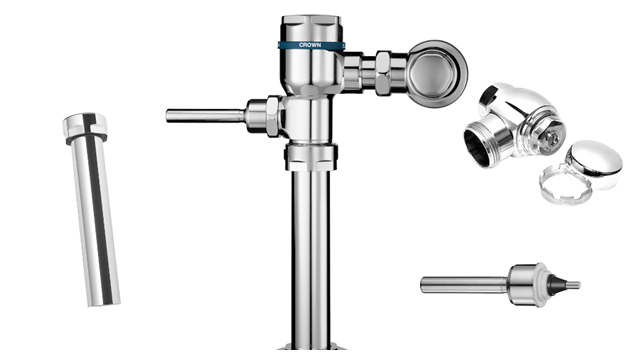

Get Diaphragm and Piston Assembly from Quality Plumbing Supply

Quality Plumbing Supply has flushometer pistons and diaphragms, including repair parts for all your new installation and maintenance projects.

If you need assistance in choosing the right flushometer for your project, email us at admin@qualityplumbingsupply.com or give us a call at 1-833-251-4591. We’re always happy to help!

At Quality Plumbing Supply, we take pride in our people, products, and services. Get in touch with us today!