Why Leonard Valve Tempering Valves?

Mar 27th 2024

Tempering valves are sometimes referred to as hot water mixing valves, and occasionally as thermostatic mixing valves.

However, they are not exactly the same and have a few differences in their design and function.

Nonetheless, and despite the name, the basic purpose behind the design of tempering valves like Leonard Valve tempering valves remains the same.

Here’s what you need to know about their purpose, how they work, and why options like Leonard Valve Company represent the highest possible value in the industry.

What Is the Purpose of a Tempering Valve System?

Water tempering valves play a very crucial role in plumbing, not only in residential and commercial settings but also in industrial settings.

Basically, a thermostatic mixing valve is a valve with inputs for both hot and cold water that mixes them upstream of the point of use.

This enables users - either people or appliances - to access water at a constant, controlled temperature, either hot or cold.

This sounds fairly straightforward but it actually has some very significant implications which have as much - if not more - to do with safety than they have to do with comfort.

The main purpose of a tempering valve is to enable a facility’s (or home’s) hot water tanks to be maintained above 140℉. More often than not, the tanks are maintained at substantially hotter temperatures, closer to 160℉.

The reason that this is necessary has to do with inhibiting the growth of harmful pathogens. Bacteria bloom in warm water, but temperatures above 140℉ are inhospitable to many microorganisms and help prevent them from blooming.

Of specific concern is Legionella, which frequently grows in warm water tanks and which can pose a substantial health risk in the event of exposure. Maintaining hot water tanks above the threshold mentioned above considerably limits this risk.

There is another consideration that must be made with respect to the implementation of a water mixing valve such as either a tempering valve or a thermostatic mixing valve, and that has to do with the safety of exposure to hot water.

While it is vital to maintain hot water tanks above a certain temperature to inhibit the growth of bacteria, it is also important to prevent scalds, which can occur at substantially lower temperatures and which can cause injuries that can become infected.

Tempering valves and thermostatic mixing valves enable the facility’s hot water tanks to be maintained above a given temperature, mixing hot and cold water before the point of use to prevent scalds and ensure comfort.

What Makes Leonard Valve Tempering Valves Different?

Since 1911, Leonard Valve tempering valves have been made in America and Leonard Valve Company has continuously striven to create plumbing products that comply with the standards proscribed by the American Society of Sanitary Engineers (ASSE).

This commitment applies to Leonard Valve tempering valves as much as their other plumbing products and there are numerous reasons that Leonard Valve is considered a premier manufacturer in its industry.

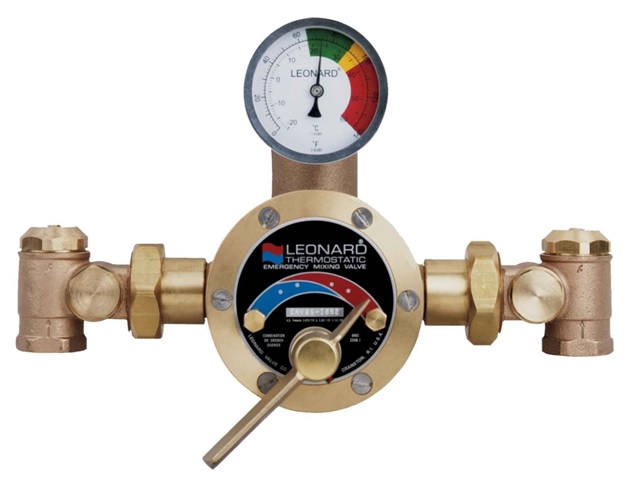

For one thing, Leonard Valve's tempering valves embody quality. Many of them are made with lead-free bronze bodies which are mechanically durable and corrosion-resistant. Select Leonard Valves are made with bronze and feature stainless steel and brass internal parts.

Many of them also have copper-encapsulated thermostat assemblies with durable polymer thermoplastic shuttles, making them chemically, physically, and thermally durable. Some Leonard Valve tempering valves are made with stainless steel springs and integral check valves on hot and cold inlets.

Other Leonard tempering valves feature DURA-trol solid bimetal thermostats that are extremely durable and which are impervious to heat damage and contain a color-coded dial.

Even on simple models, tempering valves are made with temperature selector handles that are easy to operate and read and which are marked “COLD-HOT,” for ease of use.

Many of Leonard Valve’s tempering valves feature full-port ball valves on the inlet piping for both the hot and cold water supply.

In addition, many Leonard Valve hot water mixing valves are mounted on galvanized struts which are strong and corrosion resistant. Their mixing valves are also factory-assembled and tested as complete systems prior to sale.

Most importantly, Leonard Valves are produced according to a wide range of needs, and are made in a wide variety of configurations and specifications, in a range of inlet and outlet sizes, and with varying specifications with respect to operating conditions, temperature and flow rate.

Moreover, the fact that Leonard Valve has staunchly committed to meeting the various standards set by the ASSE is another reason that their valves are so widely trusted in the industry.

High-Quality Leonard Valve Tempering Valves at Affordable Prices

Interested in learning more about what distinguishes Leonard Valve’s products in an industry that is not only competitive but which is defined by adherence to standards and certifications?

Get in touch with us at 1-833-251-4591 or create an account to start saving on essential Leonard Valve products today.